Types of Cabinet Door Bit Sets

Selecting the appropriate cabinet door bit set is crucial for achieving clean, precise cuts and a professional finish. The choice depends heavily on the desired door style, the material being used, and the level of detail required. Understanding the differences between available bit types and materials is essential for successful woodworking projects.

Router Bits vs. Drill Bits for Cabinet Doors

Router bits and drill bits serve distinct purposes in cabinet door construction, although both can contribute to the overall process. The following table summarizes their key differences:

| Bit Type | Material Compatibility | Typical Applications | Advantages/Disadvantages |

|---|---|---|---|

| Router Bits | Wood, plywood, MDF, hardwoods | Creating profiles, rabbets, dados, raised panels, decorative edges | Advantages: Precise cuts, versatile shaping capabilities. Disadvantages: Requires a router, can be more expensive than drill bits, requires more skill to operate safely. |

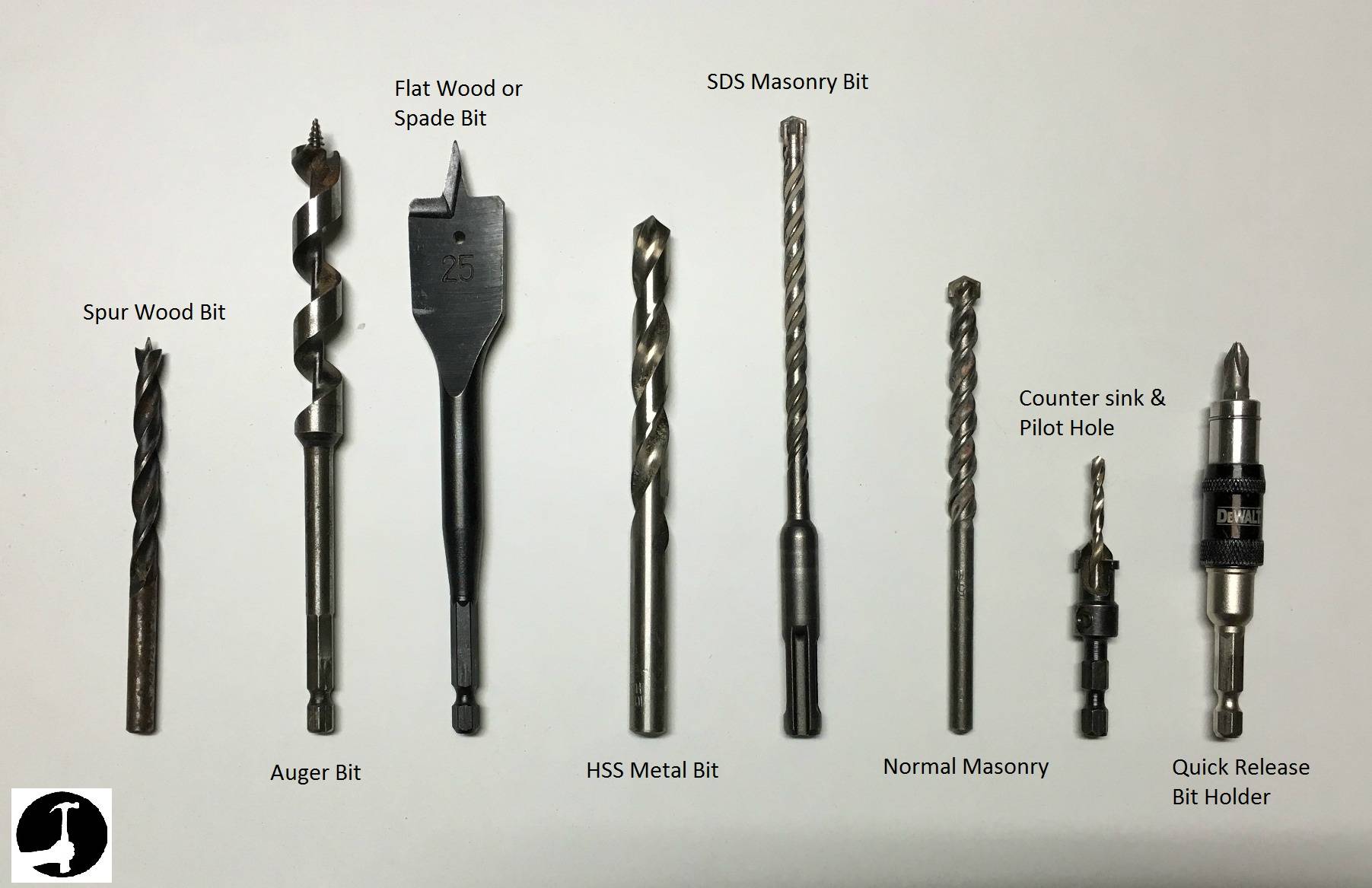

| Drill Bits | Wood, plywood, MDF, some hardwoods (depending on bit type and hardness) | Drilling pilot holes, creating hinge mortises, pocket holes | Advantages: Simple to use, relatively inexpensive. Disadvantages: Limited shaping capabilities, less precise for detailed work than router bits. |

Cabinet Door Styles and Required Bit Sets

The style of cabinet door significantly impacts the type of bit set needed. Each style necessitates specific bit profiles to achieve its unique aesthetic.

Cabinet door bit set – The following sections detail the bits required for each style:

Raised Panel Cabinet Doors

Raised panel doors feature a recessed central panel surrounded by a raised frame. Creating this requires a range of router bits.

- Panel raising bit: This creates the concave profile of the raised panel.

- Rail and stile bits: These shape the frame surrounding the panel, often with a decorative profile.

- Flush trim bit: Used to create a clean, flush surface between the panel and the frame.

- Rounding over bit (optional): Used to soften the edges of the rails and stiles.

Flat Panel Cabinet Doors

Flat panel doors, as the name suggests, feature a flat central panel. While simpler than raised panel doors, they still require specific bits.

- Straight bit: For creating clean, straight cuts on the rails and stiles.

- Dado stack: For creating grooves to receive the panel.

- Rounding over bit (optional): To soften the edges.

Shaker Style Cabinet Doors

Shaker style doors are characterized by their simple, clean lines and flat panels framed by a raised edge.

- Straight bit: For creating the frame and the flat panel.

- Edge-forming bit: Creates the raised edge around the flat panel.

- Rounding over bit (optional): For softening the edges.

Cabinet Door Bit Set Materials

The material of the bits significantly influences their durability and lifespan.

Two common materials are carbide and high-speed steel (HSS).

Carbide-tipped bits are significantly more durable than HSS bits. They can withstand significantly more use before showing wear, particularly when working with hardwoods. Carbide bits retain their sharpness much longer, resulting in cleaner cuts and a longer lifespan, even when working with abrasive materials. However, they are generally more expensive than HSS bits. A high-quality carbide bit can easily last for hundreds of projects, while a comparable HSS bit might require replacement after significantly fewer uses, especially when working with harder woods. The initial higher cost of carbide bits is often offset by their extended lifespan and superior performance.

HSS bits, while less durable than carbide, offer a more affordable option, particularly for occasional use or smaller projects. They are suitable for softer woods and less demanding applications. However, their sharpness degrades more quickly, leading to less precise cuts and potentially requiring more frequent sharpening or replacement.

Using Cabinet Door Bit Sets

Cabinet door bit sets offer a precise and efficient method for crafting custom cabinet doors, enabling both professional and amateur woodworkers to achieve high-quality results. Understanding the proper techniques and safety measures is crucial for successful and safe operation. This section details the process of creating a raised panel cabinet door using a cabinet door bit set, highlighting crucial techniques and potential pitfalls.

Creating a Raised Panel Cabinet Door

The following steps Artikel the process of crafting a raised panel cabinet door using a cabinet door bit set. Accurate measurement and careful execution are essential for achieving a professional finish.

- Prepare the Door Stock: Begin by selecting appropriately sized and dried lumber for the door stiles, rails, and panel. Ensure the wood is free of knots or imperfections that could interfere with the routing process. Plane the wood to the desired thickness and width, paying close attention to achieving perfectly square edges.

- Assemble the Frame: Using wood glue and clamps, carefully assemble the stiles and rails to form the door frame. Ensure the joints are tight and square. Allow the glue to dry completely according to the manufacturer’s instructions.

- Route the Panel Groove: Once the glue is dry, carefully measure and mark the location of the panel groove on the inside edges of the frame. Using the appropriate router bit from your cabinet door bit set (typically a rabbeting bit or a panel raising bit with a bearing), route the groove to the precise depth and width required for your panel. Ensure the router is securely clamped to the router table or work surface and that the bit is properly aligned.

- Cut the Panel: Cut the raised panel to fit snugly within the routed groove. The panel should be slightly smaller than the groove to allow for expansion and contraction. Use a sharp saw to achieve clean, straight cuts.

- Install the Panel: Carefully insert the raised panel into the groove. Apply a small amount of wood glue to ensure a tight fit. Use clamps to hold the panel in place until the glue dries completely.

- Sand and Finish: Once the glue is dry, carefully sand the entire door, paying close attention to the edges and corners. Apply your desired finish to protect the wood and enhance its appearance.

Achieving Precise Cuts and Avoiding Common Mistakes

Achieving precise cuts with cabinet door bit sets requires attention to detail and proper technique. Several common mistakes can lead to inaccurate cuts and damaged workpieces.

Always wear appropriate safety gear, including safety glasses and hearing protection, when using power tools. Securely clamp your workpiece to prevent movement during routing.

- Mistake: Incorrect bit depth setting. This can lead to shallow or deep grooves, affecting the fit of the panel and the overall appearance of the door. Solution: Carefully measure and set the bit depth using a depth gauge or other measuring tool. Always test the bit setting on a scrap piece of wood before working on the actual door.

- Mistake: Improper router speed. Too fast a speed can cause burning or tear-out, while too slow a speed can lead to uneven cuts. Solution: Consult the manufacturer’s recommendations for the appropriate speed for the specific bit and material being used.

- Mistake: Insufficient clamping pressure. This can cause the workpiece to move during routing, resulting in inaccurate cuts. Solution: Use ample clamps to securely hold the workpiece in place, preventing any movement during the routing process.

Bit Selection for Different Cabinet Door Styles and Materials

The choice of cabinet door bit type and size depends on the specific style and material of the cabinet door being constructed. The following table provides guidance on bit selection for various applications.

| Door Style | Material | Recommended Bit Type | Bit Size (inches) |

|---|---|---|---|

| Raised Panel | Hardwood (Oak, Maple) | Panel Raising Bit | 1/2″ – 3/4″ |

| Flat Panel | Softwood (Pine, Fir) | Straight Bit | 1/4″ – 1/2″ |

| Shaker | Medium Density Fiberboard (MDF) | Flush Trim Bit | 1/4″ – 1/2″ |

| Inset | Plywood | Rabbetting Bit | 1/4″ – 3/8″ |

Maintenance and Care of Cabinet Door Bit Sets

Proper maintenance is crucial for extending the lifespan of your cabinet door bit sets and ensuring consistently clean cuts. Neglecting care will lead to premature wear, dull bits, and ultimately, subpar results in your woodworking projects. This section details the best practices for maintaining your valuable tools.

Sharpening Cabinet Door Bits

Maintaining the sharpness of your cabinet door bits is paramount for achieving precise, clean cuts. Dull bits tear the wood, creating ragged edges and requiring more effort from the router. Sharpening can be accomplished using several methods. For most hobbyists, a bench grinder with a fine grit wheel is sufficient. However, for intricate profiles, professional sharpening services may be necessary to ensure the original geometry of the bit is preserved. Remember to always follow the manufacturer’s instructions for sharpening, paying close attention to the bit’s angle and speed to avoid damage. Improper sharpening can easily ruin a bit.

Cleaning and Storage of Cabinet Door Bits

Cleaning your bits after each use is essential to prevent the accumulation of pitch, sawdust, and resin. These materials can not only dull the bits but also interfere with their proper function. A stiff brush and a solvent such as mineral spirits are effective for removing debris. Thoroughly dry the bits before storage. Storing your bits properly is also critical to their longevity. A dedicated storage case with individual slots for each bit will prevent damage and keep them organized. Avoid storing bits in damp or humid environments, as this can lead to rust and corrosion, particularly on bits made of uncoated steel.

Signs of Wear and Tear in Cabinet Door Bit Sets

Identifying the signs of wear and tear is crucial for preventing damage to your work and ensuring the safety of your tools. Ignoring these signs can lead to dangerous kickback and ruined projects.

Checklist for Worn or Damaged Cabinet Door Bits

Regularly inspect your bits for the following:

- Chipped or broken cutting edges: This is a clear sign that the bit needs to be sharpened or replaced. Even small chips can significantly impact the quality of the cut.

- Rounded or dull cutting edges: Dull bits will not cut cleanly, resulting in rough edges and tear-out. They also require more force, increasing the risk of kickback.

- Excessive vibration during use: Vibration can indicate a problem with the bit’s balance or sharpness. It can also damage the router itself.

- Burning or scorching of the wood: This usually indicates that the bit is dull or the router speed is too high. Overheating can damage both the bit and the wood.

- Rust or corrosion: This is a sign of improper storage and can significantly weaken the bit’s structure.

- Bent shanks: A bent shank will affect the bit’s ability to cut cleanly and safely. It can also cause damage to the router collet.